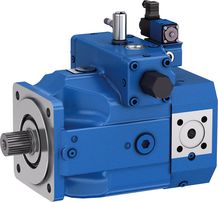

Fixed pumps

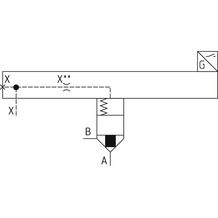

- All-purpose high pressure pump

- Size 5 … 1000

- Nominal pressure up to 400 bar

- Maximum pressure up 450 bar

- Open circuit

- Metric version

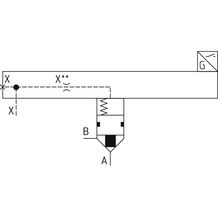

- All-purpose high pressure pump

- Size 10 … 250

- Nominal pressure up to 400 bar

- Maximum pressure up 450 bar

- Open circuit

- SAE version (for the US market)

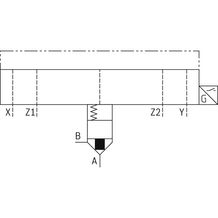

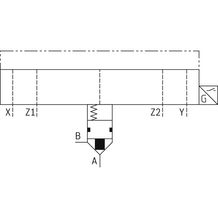

- All-purpose high pressure pump with through drive

- Size 22 … 500

- Nominal pressure up to 400 bar

- Maximum pressure up 450 bar

- Open circuit

- Suitable for variable-speed operation with synchronous and asynchronous motors

- Size 6 … 63

- Nominal pressure 315 bar

- Maximum pressure up 350 bar

- Open circuit

- Suitable for variable-speed operation with synchronous and asynchronous motors

- Size 6 … 63

- Nominal pressure 315 bar

- Maximum pressure up 350 bar

- Open circuit

Variable pumps, open circuit

- For load-sensing systems in smaller mobile machines

- Size 18 … 35

- Nominal pressure 250 bar

- Maximum pressure 280 bar

- Open circuit

- Optimized high pressure pump for maximal power requirements up to 500 bar

- Size 71 … 450

- Nominal pressure 450 bar

- Maximum pressure 500 bar

- Open circuit

- Robust high pressure pump for industrial applications

- Size 40 … 1000

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- Open circuit

- Metric version

- Robust high pressure pump for industrial applications

- Size 40 … 355

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- Open circuit

- SAE version (for the US market)

- Robust high pressure pump for universal use

- Size 28 … 500

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- Open circuit

- For machines with medium pressure requirements

- Size 10 … 100

- Nominal pressure 250 bar

- Maximum pressure 315 bar

- Open circuit

- All-purpose medium pressure pump

- Size 18 … 140

- Nominal pressure 280 bar

- Maximum pressure 350 bar

- Open circuit

- Metric version

- All-purpose medium pressure pump

- Size 18 … 140

- Nominal pressure 280 bar

- Maximum pressure 350 bar

- Open circuit

- SAE version (for the US market)

- Optimized medium pressure pump for high power machines

- Size 45 … 180

- Nominal pressure 280 bar

- Maximum pressure 350 bar

- Open circuit

- Suitable for variable-speed operation with synchronous and asynchronous motors

- Size 10 … 180

- Nominal pressure up to 280 bar

- Maximum pressure up 350 bar

- Open circuit

- All-purpose high pressure pump with through drive

- Size 110 … 280

- Nominal pressure 350 bar

- Maximum pressure 420 bar

- Open circuit

- Axial piston variable pump

- Size 12 … 107

- Nominal pressure 250 bar

- Maximum pressure 315 bar

- Open and closed design

Variable pumps, closed circuit

- Robust high pressure pump for industrial applications

- Size 40 … 1000

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- Closed circuit

- Metric version

- Robust high pressure pump for industrial applications

- Size 40 … 355

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- Closed circuit

- SAE version (for the US market)

- Robust high pressure pump with integrated boost pump

- Size 250 … 750

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- Closed circuit

- Metric version

- Robust high pressure pump with integrated boost pump

- Size 250 … 355

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- Closed circuit

- SAE version (for the US market)

- Suitable for variable-speed operation with synchronous and asynchronous motors

- Size 10 … 63

- Closed circuit

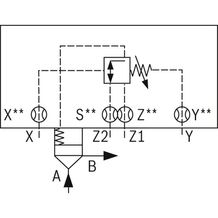

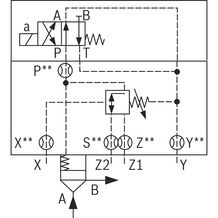

Control systems for A4VS

Accessories

- For flushing out hydraulic fluid and dirt particles from the closed circuit

- Size 40 … 90

- Nominal pressure 400 bar

- Maximum pressure 450 bar

- Closed circuit

- For the power limiting of variable pumps with hydraulic proportional control

- Size 6

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- 2-spring-power controller

- For hydrostatic fan drives in buses

- Steel or polymer versions

- Total volume 8 liters

- Maximum pressure 400 bar

- Flow rate up to 90 l/min

External gear pumps

- Platform F

- Fixed displacement

- Size 4 … 28

- Continuous pressure up to 250 bar

- Intermittent pressure up to 280 bar

- Platform N

- Fixed displacement

- Size 20 … 36

- Continuous pressure up to 250 bar

- Intermittent pressure up to 280 bar

- Platform G

- Fixed displacement

- Size 22 … 100

- Continuous pressure up to 250 bar

- Intermittent pressure up to 280 bar

- Platform F

- Fixed displacement

- Size 4 … 28

- Continuous pressure up to 250 bar

- Intermittent pressure up to 280 bar

- Platform N

- Fixed displacement

- Size 20 … 36

- Continuous pressure up to 250 bar

- Intermittent pressure up to 280 bar

- Platform F

- Low noise fixed pump

- Size 12 … 28

- Continuous pressure up to 250 bar

- Intermittent pressure up to 280 bar

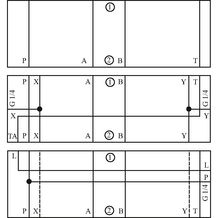

- Individual configuration of multiple external gear pumps

- Two or three-way pumps configurable

- Shipping within 10 working days

- Documentation of all key technical data

- Configured external gear pump is presented as a dimensional 2D drawing and 3D model

Internal gear pumps

PGF Series 2X and 3X

- Frame size 1, 2, 3

- Size 1.7 … 40

- Component series 2X, 3X

- Maximum operating pressure 250 bar

- Maximum displacement 40.5 cm³

Download PDF

PGH-2X

- Frame size 1, 2, 3

- Size 1.7 … 40

- Component series 2X, 3X

- Maximum operating pressure 250 bar

- Maximum displacement 40.5 cm³

Download PDF

PGH-3X

- Frame size 4, 5

- Size 20 … 250

- Component series 3X

- Maximum operating pressure 350 bar

- Maximum displacement 250.5 cm³

Download PDF

PGM-4X

- Frame size 4, 5

- Size 25 … 125

- Component series 4X

- Maximum operating pressure 210 bar

- Maximum displacement 125.3 cm³

Download PDF

PGP

- Fixed displacement

- Frame size 2, 3

- Size 6.3 … 32

- Maximum pressure 350 bar

- Displacement 6.5 … 32.5 cm³

Download PDF

Gerotor pumps

Gerotor pumps are used in the low-pressure range up to 15 bar. They are often used in connection with other Rexroth pumps in cooling, filter or lubrication circuits.

Gerotor pumps with constant displacement PGZ

- Frame size 4, 5

- Size 20 … 140

- Maximum operating pressure 15 bar

- Maximum displacement 136.3 cm³

Download PDF

Vane Pumps

Vane pumps are available in a wider range of sizes. They are used in applications requiring medium operating pressures and low noise emissions.

Adjustable, pilot operated PV7...C/D/N/W

- Frame size 10, 16, 25, 40, 63, 100

- Size 14 … 150

- Component series 1X

- Maximum operating pressure 160 bar

- Maximum displacement 150 cm³

Download PDF

Variable, direct controlled PV7...A

- Frame size 06, 20

- Size 10 … 25

- Component series 1X, 2X

- Maximum operating pressure 100 bar

- Maximum displacement 25 cm³

- Maximum flow 36 l/min

Download PDF

Fixed displacement vane pumps PVV

- Frame size 1, 2, 4, 5

- Size 18 … 193

- Component series 1X

- Maximum operating pressure 210 bar

- Maximum displacement 193.4 cm³

- Maximum flow 285 l/min

Download PDF

Fixed displacement vane pumps PVQ

- Frame size 1, 2, 4, 5

- Size 18 … 193

- Component series 1X

- Maximum operating pressure 210 bar

- Maximum displacement 193.4 cm³

- Maximum flow 285 l/min

Download PDF

Fixed displacement vane pumps PVH

- Fixed displacement

- Frame size 1, 2

- Size 16 … 79

- Nominal pressure 290 bar

- Maximum pressure 320 bar

- Displacement 15.9 … 79.3 cm³

Download PDF

Radial piston pumps

Radial piston pumps are characterized by very high operating pressures of up to 700 bar. The volume flows of the individual pistons can be used for various tasks.

Radial piston pumps, fixed displacement PR4-1X

- Size 0,40 … 2,00

- Component series 1X

- Maximum operating pressure 700 bar

- Maximum displacement 2 cm³

Download PDF

Radial piston pumps, fixed displacement PR4-3X

- Size 1,60 … 20,00

- Component series 3X

- Maximum operating pressure 700 bar

- Maximum displacement 19.43 cm³

Download PDF

Electrohydraulic pumps

Electrohydraulic pump EHP

- Drive unit for vehicles and material handling systems

- Fixed pump with electric motor

- Size pump 1.0 … 22

- Intermittent pressure up to 280 bar

- Nominal voltage 12 … 110 V

Download PDF

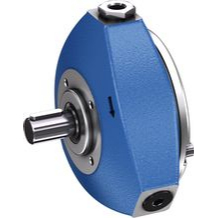

Radial piston motors

Our Hägglunds direct drive hydraulic motors stand for unparalleled quality and reliability. Moreover, innovation at Bosch Rexroth is inspired by our clients’ challenges and our goal is to deliver to them products that exceed performance and reliability expectations.

CA

- Size 7 … 210

- Displacement 1256 … 13200 cm³/rev

- Specific torque 20 … 210 Nm/bar

- Maximum operating pressure 350 bar

Download PDF

CBP

- Size 80 … 840

- Displacement 5024 … 52800 cm³/rev

- Specific torque 80 … 840 Nm/bar

- Maximum operating pressure 350 bar

Download PDF

CB

- Size 240 … 1120

- Displacement 15100 …

70400 cm³/rev - Specific torque 240 … 1120 Nm/bar

- Maximum operating pressure 350 bar

Download PDF

VI

- Size 03300 … 38000

- Displacement 3325 … 38000 cm³/rev

- Specific torque 53 … 605 Nm/bar

- Nominal speed 25 … 100 rpm

- Maximum operating pressure 320 bar

Download PDF

Axial piston motors

Axial piston motors are available in swash plate or bent axis design for

medium- and high-pressure applications.

Our hydrostatic drives for mobile and stationary application ranges stand

out due to their robustness, reliability, long life cycles, low noise

emissions and high efficiencies as well as high cost-effectiveness.

Fixed motors

A2FM series 6x

- All-purpose high pressure motor

- Size 5 … 1000

- Nominal pressure up to 400 bar

- Maximum pressure up 450 bar

- Open and closed circuits

Download PDF

A2FE series 6x

- High pressure motor for integration in mechanical gearboxes

- Size 28 … 355

- Nominal pressure up to 400 bar

- Maximum pressure up 450 bar

- Open and closed circuits

Download PDF

A2FM series 70

- Compact high pressure motor with short installation length

- Size 45 … 107

- Nominal pressure up to 450 bar

- Maximum pressure up 500 bar

- Open and closed circuits

Download PDF

A2FE series 70

- Compact high pressure motor for integration in mechanical gearboxes

- Size 45 … 107

- Nominal pressure up to 450 bar

- Maximum pressure up 500 bar

- Open and closed circuits

Download PDF

A4FM

- High pressure motor for confined installation spaces

- Size 22 … 500

- Nominal pressure up to 400 bar

- Maximum pressure up 450 bar

- Open and closed circuits

Download PDF

A10FM series 52

- Medium pressure motor for standard applications

- Size 18 … 63

- Nominal pressure 280 bar

- Maximum pressure 350 bar

- Open and closed circuits

Download PDF

A10FE series 52

- Medium pressure motor for integration in mechanical gearboxes

- Size 10 … 63

- Nominal pressure 280 bar

- Maximum pressure 350 bar

- Open and closed circuits

Download PDF

Variable motors

A6VM series 6x

- All-purpose high pressure motor

- Size 28 … 1000

- Nominal pressure up to 400 bar

- Maximum pressure up 450 bar

- Open and closed circuits

Download PDF

A6VM series 71

- All-purpose high pressure motor

- Size 60 … 280

- Nominal pressure 450 bar

- Maximum pressure 500 bar

- Open and closed circuits

Download PDF

A10VM series 52

- Medium pressure motor with two-point control

- Size 28 … 85

- Nominal pressure 280 bar

- Maximum pressure 350 bar

- Open and closed circuits

Download PDF

A10VE series 52

- Plug-in medium pressure motor with two-point control

- Size 28 … 63

- Nominal pressure 280 bar

- Maximum pressure 350 bar

- Open and closed circuits

Download PDF

A10VER series 52

- Reversible axial piston motor for fan drives

- Size 18 … 45

- Nominal pressure 280 bar

- Maximum pressure 350 bar

- Open circuit

Download PDF

Accessories

Counterbalance valve BVD 20-25

- Double acting for travel drives and winch drives

- Size 20 … 25

- Nominal pressure 350 bar

- Maximum pressure 420 bar

- Direct attachment on Rexroth axial piston motors (A2FM / A2FE / A6VM / A6VE)

Download PDF

Counterbalance valve BVE 25

- Single acting for controlled load lowering in winch drives

- Size 25

- Nominal pressure pump side 350 bar

- Nominal pressure motor side 420 bar

- Direct attachment on Rexroth axial piston motors (A2FM / A2FE / A6VM / A6VE)

Download PDF

Counterbalance valve BVD/BVE 32

- Double acting for track drives (BVD) and single acting for winch drives (BVE)

- Size 32

- Nominal pressure pump side 350 bar

- Nominal pressure motor side 450 bar

- Direct attachment on Rexroth axial piston motors (A6VM / A6VE)

Download PDF

Neutral position switch NLS

- Switch for detecting the neutral position

- For installation in Rexroth axial piston motors A6VM series 65 and series 71

- Protection class IP67 / IP69K

Download PDF

Isolator valves

Check valves

Z1S 6

- Size 6

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 40 l/min

Download PDF

Z1S 10

- Size 10

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 100 l/min

Download PDF

M-SR 6...30

- Size 6 … 30

- Component series 1X

- Maximum operating pressure 420 bar

- Maximum flow 400 l/min

Download PDF

Z2S 6

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

Z2S 10

- Size 10

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 120 l/min

Download PDF

Z2S 16

- Size 16

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 300 l/min

Download PDF

Z2S 22

- Size 25

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 450 l/min

Download PDF

SV 6

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

SV 10...32

- Size 10 … 32

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 550 l/min

Download PDF

SL 6

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

SL 10...32

- Size 10 … 32

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 550 l/min

Download PDF

L–S 40…300

- Size 40 … 300

- Component series 1X

- Maximum operating pressure 16 bar

- Maximum flow 50000 l/min

Download PDF

SHUT-OFF VALVES

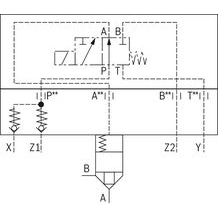

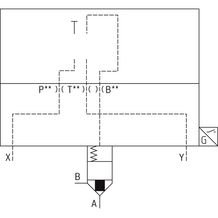

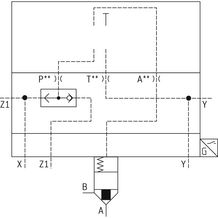

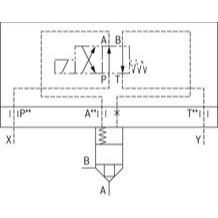

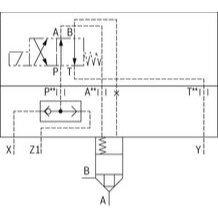

4/2 and 4/3 directional shut-off valve Z4WE 6

- Size 6

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 50 l/min

Download PDF

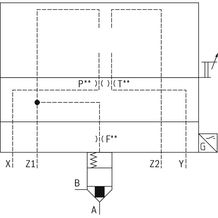

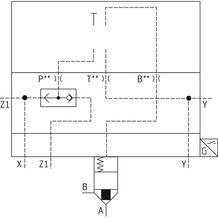

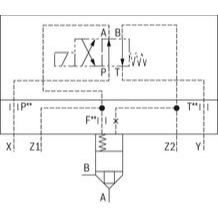

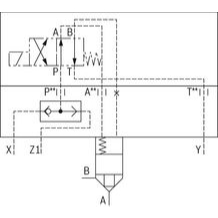

externally pilot-operated Z4WH 10

- Size 10

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 160 l/min

Download PDF

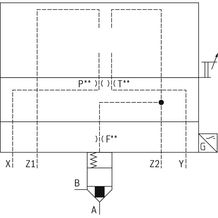

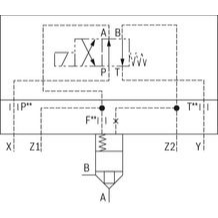

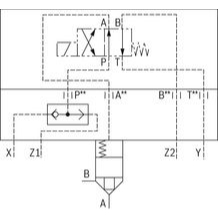

externally pilot-operated Z4WEH 10

- Size 10

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 160 l/min

Download PDF

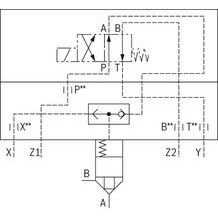

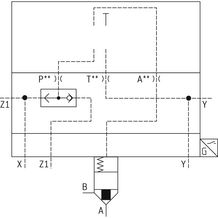

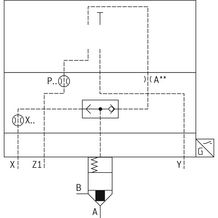

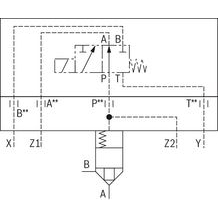

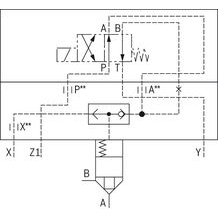

externally pilot-operated Z4WH 16

- Size 16

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 300 l/min

Download PDF

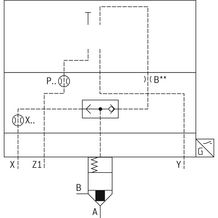

externally pilot-operated Z4WEH 16

- Size 16

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 300 l/min

Download PDF

externally pilot-operated Z4WH 22

- Size 25

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 650 l/min

Download PDF

externally pilot-operated Z4WEH 22

- Size 25

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 650 l/min

Download PDF

Prefill valves

Prefill valve, sandwich plate design ZSF

- Size 32 … 200

- Component series 1X, 2X

- Maximum operating pressure 350 bar

- Maximum flow 7000 l/min

Download PDF

Prefill valve - sandwich plate ZSFW

- Size 32 … 200

- Component series 1X, 2X

- Maximum operating pressure 350 bar

- Maximum flow 7000 l/min

Download PDF

Prefill valve SF

- Size 125 … 500

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 50000 l/min

Download PDF

Prefill valves SFA

- Size 25 … 80

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 1200 l/min

Download PDF

Prefill valves SFE

- Size 25 … 100

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 2000 l/min

Download PDF

actively switchable SFS

- Size 200 … 300

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 14000 l/min

Download PDF

Directional valves

Directional valves controlling the flow direction and thus the direction of movement or rotation of hydraulic actuators (directional seat valves or spool valves, direct operated or pilot operated).

Directional seat valves

Direct Operated

SEC 6

- Size 6

- Component series 1X

- Maximum operating pressure 420 bar

- Maximum flow 25 l/min

Download PDF

M-.SED6

- Size 6

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 25 l/min

Download PDF

SED 6…XN

- Size 6

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 25 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Area of application according to technical rules EAC TR CU 012/2011: II 3G; II 3D

- Type of protection of the valve

solenoids:

– Ex ec IIC T3 Gc according to EN 60079-7

– Ex tc IIIC T140°C Dc according to EN 60079-31

Download PDF

M-.SED 10

- Size 10

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 40 l/min

Download PDF

SED 10…XN

- Size 10

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 40 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Area of application according to technical rules EAC TR CU 012/2011: II 3G; II 3D

- Type of protection of the valve

solenoids:

– Ex ec IIC T3 Gc according to EN 60079-7

– Ex tc IIIC T140°C Dc according to EN 60079-31

Download PDF

M-.SEW 6

- Size 6

- Component series 3X

- Maximum operating pressure 420 / 630 bar

- Maximum flow 25 l/min

Download PDF

M-.SEW 10

- Size 10

- Component series 1X

- Maximum operating pressure 420 / 630 bar

- Maximum flow 40 l/min

Download PDF

E-.SE6

- Size 6

- Component series 7X

- Maximum operating pressure 420 / 630 bar

- Maximum flow 25 l/min

Download PDF

E-.SE 6 ...X...

- Size 6

- Component series 6X

- Maximum operating pressure 420 bar

- Maximum flow 4 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve: Ex ib I Mb / Ex ib IIC T6 Gb according to EN 60079-0 / EN 60079-11

Download PDF

W-.SE6

- Size 6

- Component series 7X

- Maximum operating pressure 630 bar

- Maximum flow 25 l/min

Download PDF

M-.SMM

- Size 10, 6

- Component series 3X

- Maximum operating pressure 420 / 630 bar

- Maximum flow 40 l/min

Download PDF

M-.SMR

- Size 10, 6

- Component series 3X

- Maximum operating pressure 420 / 630 bar

- Maximum flow 40 l/min

Download PDF

M-.SH

- Size 10, 6

- Component series 3X

- Maximum operating pressure 420 / 630 bar

- Maximum flow 40 l/min

Download PDF

M-.SP

- Size 10, 6

- Component series 3X

- Maximum operating pressure 420 / 630 bar

- Maximum flow 40 l/min

Download PDF

KSDE.8 N/P (High Performance)

- Size 8

- Component series B

- Maximum operating pressure 500 bar

- Maximum flow 5 l/min

Download PDF

KSDER0 N/P (High Performance)

- Size 1

- Component series B

- Maximum operating pressure 500 bar

- Maximum flow 20 l/min

Download PDF

KSDE.1 N/P (High Performance)

- Size 1

- Component series B

- Maximum operating pressure 500 bar

- Maximum flow 20 l/min

Download PDF

KSDE. 1C/U (High Performance)

- Size 1

- Component series B

- Maximum operating pressure 350 bar

- Maximum flow 20 l/min

Download PDF

Pilot-operated

M-Z4SEH

- Size 10, 16

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 300 l/min

Download PDF

ABZAW

- Nominal width 8 … 50

- Component series 1X

- Maximum operating pressure 16 bar, 10 bar

Download PDF

Directional spool valves

Direct Operated

WE 6...E

- Size 6

- Component series 6X

- Maximum operating pressure 350 bar

- Maximum flow (DC) 80 l/min

- Maximum flow (AC) 60 l/min

Download PDF

WE 6...H

- Size 6

- Component series 7X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WE 10...E

- Size 10

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 160 l/min

Download PDF

5-.WE

- 5-chamber version

- Size 10

- Component series 5X

- Maximum operating pressure 420 bar

- Maximum flow 150 l/min

Download PDF

WE 6...H

- Size 6

- Component series 7X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WE 6 ../.B..XD...

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve solenoids: Ex db I Mb / Ex db IIC T4 Gb according to EN 60079-0 / EN 60079-1

Download PDF

WE 6 …E..XE

- Size 6

- Component series 6X

- Maximum operating pressure 350 bar

- Maximum flow 80 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Area of application according to technical rules EAC TR CU 012/2011: II 3G; II 3D

- Type of protection of the valve

solenoids:

– Ex ec IIC T3 Gc according to EN 60079-7

– Ex tc IIIC T140°C Dc according to EN 60079-31

Download PDF

WE 6 ../.B..XH...

- Size 6

- Component series 5X

- Maximum operating pressure 210 bar

- Maximum flow 20 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve: Ex ib I Mb / Ex ib IIC T6 Gb according to EN 60079-0 / EN 60079-11

Download PDF

WE 6 ../.B..XD...

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve solenoids: Ex db I Mb / Ex db IIC T4 Gb according to EN 60079-0 / EN 60079-1

Download PDF

WE 6 …E..XE

- Size 6

- Component series 6X

- Maximum operating pressure 350 bar

- Maximum flow 70 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve solenoids: Ex eb mb IIC T4 Gb according to EN 60079-7 / EN 60079-18

Download PDF

WE 6 …E..XN

- Size 6

- Component series 6X

- Maximum operating pressure 350 bar

- Maximum flow 80 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Area of application according to technical rules EAC TR CU 012/2011: II 3G; II 3D

- Type of protection of the valve

solenoids:

– Ex ec IIC T3 Gc according to EN 60079-7

– Ex tc IIIC T140°C Dc according to EN 60079-31

Download PDF

WE 6 ../.B..XH...

- Size 6

- Component series 5X

- Maximum operating pressure 210 bar

- Maximum flow 20 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve: Ex ib I Mb / Ex ib IIC T6 Gb according to EN 60079-0 / EN 60079-11

Download PDF

WE 6 ../.B..XM...

- Size 6

- Component series 5X

- Maximum operating pressure 210 bar

- Maximum flow 20 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve: Ex ib I Mb / Ex ib IIC T6 Gb according to EN 60079-0 / EN 60079-11

Download PDF

WH 6

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WH 6...XC

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2, II 2G, II 2D, II 3G, II 3D

- Type of protection of the valve solenoids: c (EN 13463-5)

Download PDF

WHZ 6

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WP 6

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WP 6...XC

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2, II 2G, II 2D, II 3G, II 3D

- Type of protection of the valve solenoids: c (EN 13463-5)

Download PDF

WPZ 6

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WMD 6

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WMDA 6

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WMM 6

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WMM 6...XC

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2, II 2G, II 2D, II 3G, II 3D

- Type of protection of the valve solenoids: c (EN 13463-5)

Download PDF

WMR 6

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WMRZ 6

- Size 6

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WMU 6

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

WMM 10

- Size 10

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 160 l/min

Download PDF

WN 10

- Size 10

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 160 l/min

Download PDF

H-4WMM

- Size 16 … 32

- Component series 7X, 5X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

WP 10

- Size 10

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 160 l/min

Download PDF

KKDER1 N/P (High Performance)

- Size 1

- Component series A

- Maximum operating pressure 350 bar

- Maximum flow 55 l/min

Download PDF

WES

- Size 8

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum pressure drop 150 bar

- Maximum flow 200 l/min

Download PDF

KKDER1 C/U (High Performance)

- Size 1

- Component series A

- Maximum operating pressure 350 bar

- Maximum flow 60 l/min

Download PDF

KKDER1 D/E/F (High Performance)

- Size 1

- Component series A

- Maximum operating pressure 350 bar

- Maximum flow 40 l/min

Download PDF

KKDEN8 N/P (standard performance)

- Size 8

- Component series A

- Maximum operating pressure 250 bar

- Maximum flow 25 l/min

Download PDF

KKDEN8 C/G/U (standard performance)

- Size 8

- Component series A

- Maximum operating pressure 250 bar

- Maximum flow 20 l/min

Download PDF

KKDER8 N/P (High Performance)

- Size 8

- Component series A

- Maximum operating pressure 350 bar

- Maximum flow 45 l/min

Download PDF

KKDER8 N/P (High Performance)

- Size 8

- Component series A

- Maximum operating pressure 350 bar

- Maximum flow 45 l/min

Download PDF

KKDER8 C/G/U (High Performance)

- Size 8

- Component series A

- Maximum operating pressure 350 bar

- Maximum flow 30 l/min

Download PDF

VEDS-10A-43

- Size 10

- Component series 0

- Maximum operating pressure 350 bar

- Maximum flow 35 l/min

Download PDF

VEDS-10A-53

- Size 10

- Component series 0

- Maximum operating pressure 250 bar

- Maximum flow 25 l/min

Download PDF

Pilot Operated

WH, WEH

- Size 10 … 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

H-WH

- Size 10, 16, 25 (H-WH22), 25 (H-WH25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

WEH

- Size 10, 16, 25 (WEH22), 25 (WEH25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 280 bar

- Maximum flow 1100 l/min

Download PDF

H-WEH

- Size 10, 16, 25 (H-WEH22), 25 (H-WEH25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

H-WEH...=UR

- Solenoid coil is an approved component with UR-marking according to UL 906

- Size 10, 16, 25 (H-WEH22), 25 (H-WEH25), 32

- Component series 4X, 7X, 7X, 6X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

H-4WEH…XD...

- Size 10 … 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve solenoids: Ex db I Mb / Ex db IIC T4 Gb according to EN 60079-0 / EN 60079-1

Download PDF

H-4WEH…XE…

- Size 10 … 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 2G

- Type of protection of the valve solenoids: Ex eb mb IIC T4 Gb according to EN 60079-7 / EN 60079-18

Download PDF

H-4WEH...VP1

- Size 10 … 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

- Area of application according to

– NEC500 and CEC Appendix J: Class I, Division 1, Groups B, C, D T4

– NEC502 and CEC Section 18: Class II/III, Division 1, Groups E, F, G T4 - Type of protection valve solenoid: XP (explosion-proof); DIP (dust ignition protection)

Download PDF

WHH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 280 bar

- Maximum flow 1100 l/min

Download PDF

H-.WHH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

WPH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 280 bar

- Maximum flow 1100 l/min

Download PDF

H-.WPH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

WMMH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 280 bar

- Maximum flow 1100 l/min

Download PDF

H-.WMMH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

WMRH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 280 bar

- Maximum flow 1100 l/min

Download PDF

H-.WMRH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

WMUH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 280 bar

- Maximum flow 1100 l/min

Download PDF

H-.WMUH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

WMDH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 280 bar

- Maximum flow 1100 l/min

Download PDF

H-.WMDH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

WMDAH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 280 bar

- Maximum flow 1100 l/min

Download PDF

H-.WMDAH

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

LS 1376

- Size 10, 16, 25 (4W.H22), 25 (4W.H25), 32

- Component series 4X, 7X, 6X

- Maximum operating pressure 350 bar

- Maximum flow 1100 l/min

Download PDF

Pressure valves

Pressure valves having a pre-determined effect on the operating pressure in a system or a part of a system (pressure relief valves, pressure sequence valves, pressure cut-off valves and pressure reducing valves).

Pressure relief valves

Direct Operated

DBD.2K

- Size 2

- Component series 2X

- Maximum operating pressure 420 bar

- Maximum flow 2 l/min

Download PDF

DBD.4K

- Size 4

- Component series 1X

- Maximum operating pressure 500 bar

- Maximum flow 20 l/min

Download PDF

DBD.4K…SO156

- Size 4

- Component series 1X

- Maximum operating pressure 420 bar

- Maximum flow 20 l/min

Download PDF

DB6D

- Size 6

- Component series 1X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

DBDH…XC…E

- Size 6 … 30

- Component series 1X

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2, II 2G, II 2D

- Type of protection of the valve solenoids: c (EN 13463-5)

Download PDF

(Z)DBT/DZT

- Size 6

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 3 l/min

Download PDF

ZDB6D, Z2DB6D

- Size 6

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 60 l/min

Download PDF

ZDB10D, Z2DB10D

- Size 10

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 120 l/min

Download PDF

PILOT OPERATED

ZDB 6, Z2DB 6

- Size 6

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

ZDB 10, Z2DB 10

- Size 10

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 100 l/min

Download PDF

DB.K

- Size 10, 6

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow (NG6) 60 l/min

- Maximum flow (NG10) 100 l/min

Download PDF

DB20K

- Size 25

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 300 l/min

Download PDF

DB(C/T)

- Size 10 … 32

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 650 l/min

Download PDF

DBW(C/T)

- Size 10 … 32

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 650 l/min

Download PDF

DB...XC

- Size 10 … 32

- Component series 5X

- Maximum operating pressure 350 bar

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2, II 2G, II 2D

- Types of protection of the valve: c (EN 13463-5)

Download PDF

DB...W65

- Size 10 … 25

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 400 l/min

Download PDF

DBW…W65

- Size 10 … 25

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 300 l/min

Download PDF

DB52

- Size 52

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 2000 l/min

Download PDF

DBW52

- Size 52

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 2000 l/min

Download PDF

DBA…1X

- Size 32, 40

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 650 l/min

Download PDF

DBAW...1X

- Size 32, 40

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 650 l/min

Download PDF

DBA...2X

- Size 16 … 32

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 400 l/min

Download PDF

DBAW...2X

- Size 16 … 32

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 400 l/min

Download PDF

DBAE...2X

- Size 16 … 32

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 400 l/min

Download PDF

DBAEE...2X

- Size 16 … 32

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 400 l/min

Download PDF

DBAEA...2X

- Size 16 … 32

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 400 l/min

Download PDF

L–DB

- Size 40 … 300

- Component series 3X

- Maximum operating pressure 25 bar

- Maximum flow 50000 l/min

Download PDF

Pressure reducing valves

DIRECT OPERATED

KRD (High Performance)

- Size 2

- Component series B

- Maximum operating pressure 400 bar

- Maximum flow 25 l/min

Download PDF

DR 6 DP

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

ZDR 6 D...XC

- Size 6

- Component series 4X

- Maximum primary operating pressure 315 bar

- Maximum flow 50 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: I M2; II 2G

- Type of protection of the valve solenoids: c (EN 13463-5)

ZDR 6 D

- Size 6

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 50 l/min

Download PDF

DR 10 DP

- Size 10

- Component series 4X

- Maximum operating pressure 210 bar

- Maximum flow 80 l/min

Download PDF

ZDR 10 D

- Size 10

- Component series 5X

- Maximum operating pressure 210 bar

- Maximum flow 80 l/min

Download PDF

Piot Operated

DR 10 K

- Size 10

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 100 l/min

Download PDF

ZDR 10 V

- Size 10

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 100 l/min

Download PDF

DR(C)

- Size 10 … 32

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 400 l/min

Download PDF

3DR 10P

- Size 10

- Component series 6X

- Maximum operating pressure 315 bar

- Maximum flow 120 l/min

Download PDF

3DR 16P

- Size 16

- Component series 5X

- Maximum operating pressure 250 bar

- Maximum flow 220 l/min

Download PDF

Z3DR 6 V

- Size 6

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 60 l/min

Download PDF

Z3DR 10 V

- Size 10

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 120 l/min

Download PDF

Pressure cut-off valves

Pilot Operated

KAV (High Performance)

- Size 2

- Component series A

- Maximum operating pressure 350 bar

- Maximum flow 140 l/min

Download PDF

DA 6 V

- Size 6

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 40 l/min

Download PDF

DA

- Size 10 … 32

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 400 l/min

Download PDF

DAW

- Size 10 … 32

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 400 l/min

Download PDF

Pressure Sequence valves

Direct Operated

DZ 6 DP

- Size 6

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

ZDZ 6 D

- Size 6

- Component series 4X

- Maximum operating pressure 210 bar

- Maximum flow 60 l/min

Download PDF

DZ 10 DP

- Size 10

- Component series 4X

- Maximum operating pressure 210 bar

- Maximum flow 80 l/min

Download PDF

ZDZ 10 D

- Size 10

- Component series 5X

- Maximum operating pressure 210 bar

- Maximum flow 80 l/min

Download PDF

Pilot Operated

DZ

- Size 10 … 32

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 600 l/min

Download PDF

Flow Control Valves

Flow control valves controlling the flow and thus the speed of hydraulic actuators (throttle valves and flow control valves).

Throttle Valves

MG

- Size 6 … 30

- Component series 1X

- Maximum operating pressure 315 bar

- Maximum flow 400 l/min

Download PDF

MK

- Size 6 … 30

- Component series 1X

- Maximum operating pressure 315 bar

- Maximum flow 400 l/min

Download PDF

FG

- Size 16 … 32

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 400 l/min

Download PDF

FK

- Size 16 … 32

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 400 l/min

Download PDF

Z2FS 6...XC

- Size 6

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 80 l/min

- Area of application according to directive 94/9/EG I M2, II 2G, II 2D

- Type of protection of the valve: c (EN 13463-5:2004-03)

Z2FS 6

- Size 6

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 80 l/min

Download PDF

Z2FS 10

- Size 10

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 160 l/min

Download PDF

Z2FS 16

- Size 16

- Component series 3X

- Maximum operating pressure 350 bar

- Maximum flow 250 l/min

Download PDF

Z2FS 22

- Size 25

- Component series 3X

- Maximum operating pressure 350 bar

- Maximum flow 360 l/min

Download PDF

Z1FG

- Size 6

- Component series 4X

- Maximum operating pressure 315 bar

- Maximum flow 70 l/min

Download PDF

Z.FG

- Size 10

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 160 l/min

Download PDF

F

- Size 10, 5

- Component series 2X, 3X

- Maximum operating pressure 210 bar

- Maximum flow 80 l/min

Download PDF

Flow control valves

Flow control valves are used to maintain a constant flow, independent of pressure and temperature.

2FRM6A

- Size 6

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 32 l/min

Download PDF

2FRM6B

- Size 6

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 32 l/min

Download PDF

2FRM6SB

- Size 6

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 32 l/min

Download PDF

2FRM

- Size 10, 16

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 160 l/min

Download PDF

2FRH

- Size 10, 16

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 160 l/min

Download PDF

2FRW

- Size 10, 16

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 160 l/min

Download PDF

2FRM.K2

- Size 10, 6

- Component series 1X

- Maximum operating pressure 315 bar

- Maximum flow 60 l/min

Download PDF

Z2FRM

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 32 l/min

Download PDF

2-way cartridge valves

2-way cartridge valves are logic elements that have been designed for a compact block design. The power part is installed in a receiving hole of the manifold according to ISO 7368 and closed with a control cover.

Logic elements - directional function

Cartridge valves

LC (standard)

- Standard series

- Size 16 … 160

- Component series 6X, 2X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LC (high-pressure)

- High-pressure series

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 450 bar

- Maximum flow 13000 l/min

Download PDF

LC2A

- Size 16 … 125

- Component series 1X

- Maximum operating pressure 450 bar

- Maximum flow 17000 l/min

Download PDF

Control cover with spool position monitoring

LFA..E (control cover)

- Size 16 … 160

- Component series 6X, 2X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..E15 (control cover)

- Size 16 … 160

- Component series 6X, 2X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EM (control cover)

- Size 16 … 32

- Component series 7X

- Maximum operating pressure 400 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EM19 (control cover)

- Size 16 … 32

- Component series 7X

- Maximum operating pressure 400 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EH2 (control cover)

- Size 16 … 160

- Component series 6X, 2X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EWMA (control cover)

- Size 16 … 63

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EWMB (control cover)

- Size 16 … 63

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EWA (control cover)

- Size 16 … 160

- Component series 7X, 6X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EWB (control cover)

- Size 16 … 160

- Component series 7X, 6X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EHWMA2 (control cover)

- Size 16 … 63

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EHWMB2 (control cover)

- Size 16 … 63

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EGWA (control cover)

- Size 16 … 160

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EGWA (control cover)

- Size 16 … 160

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EGWB (control cover)

- Size 16 … 160

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EKWA (control cover)

- Size 16 … 160

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EKWB (control cover)

- Size 16 … 160

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..EKWB (control cover)

- Size 16 … 160

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..D7 (control cover)

- Size 16 … 80

- Component series 6X

- Maximum operating pressure 350 bar

- Maximum flow 25000 l/min

Download PDF

LFA..H2-7 (control cover)

- Size 16 … 80

- Component series 6X

- Maximum operating pressure 350 bar

- Maximum flow 25000 l/min

Download PDF

LFA..E51 (control cover)

- Size 25

- Component series 6X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..E52 (control cover)

- Size 25

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..E76 (control cover)

- Size 25

- Component series 6X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..E78 (control cover)

- Size 25

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..E79 (control cover)

- Size 25

- Component series 6X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

Control cover with spool position monitoring

LFA..D (standard)

- Standard series

- Size 16 … 160

- Component series 6X, 2X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..H1 (standard)

- Standard series

- Size 16 … 63

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..H2 (standard)

- Standard series

- Size 16 … 160

- Component series 6X, 2X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..H3

- Standard series

- Size 16 … 40

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..H4

- Standard series

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..G

- Standard series

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..R

- Standard series

- Size 25 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..RF

- Standard series

- Size 25 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..WEA

- Standard series

- Size 16 … 160

- Component series 6X, 2X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..WEB

- Standard series

- Size 16 … 125

- Component series 6X, 2X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..WEMA (standard)

Download PDF

LFA..WEMB (standard)

- Standard series

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..WECA

- Standard series

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..GWA

- Standard series

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..GWB

- Standard series

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..GWMA

- Standard series

- Size 16 … 80

- Component series 7X, 6X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

LFA..KWA

- Standard series

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

- Maximum flow 25000 l/min

Download PDF

Logic elements - pressure function

Cartridge valves

Control cover

LFA..DB..E

- Size 40 … 63

- Component series 7X

- Maximum operating pressure 400 bar

- Maximum flow 5000 l/min

Download PDF

LFA..DBW..E

- Size 32 … 63

- Component series 7X

- Maximum operating pressure 420 bar

- Maximum flow 5000 l/min

Download PDF

LFA..DBS (standard)

- Size 40 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

Download PDF

LFA..DBEM (standard)

- Size 16 … 100

- Component series 6X, 7X

- Maximum operating pressure 420 bar

Download PDF

Proportional directional valves

Proportional directional valves are available as direct operated and pilot operated valves with or without integrated electronics (OBE). Using integrated electronics, they reduce the cabling effort and simplify handling. These valves are ideal for many closed loop applications.

Proportional directional valves, direct operated

4WRA

- Size 6, 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 75 l/min

Download PDF

4WRAE

- Size 6, 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 75 l/min

Download PDF

4WRA ...XE

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 22 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 2G

- Type of protection of the valve solenoids: Ex eb mb IIC T4 Gb according to EN 60079-7 / EN 60079-18

Download PDF

4WRE

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 80 l/min

Download PDF

4WREE

- Size 6, 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

Download PDF

4WREE-3X

- Size 6

- Component series 3X

- Maximum operating pressure 350 bar

- Maximum flow 80 l/min

- Nominal flow (Δp = 10 bar) 4 … 32 l/min

Download PDF

4WREEM

- Size 6, 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

Download PDF

4WREF

- Size 6, 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

Download PDF

KKDSR1

- Size 1

- Component series B

- Maximum operating pressure 350 bar

- Maximum flow 38 l/min

Download PDF

KKDSR2

- Size 2

- Component series A

- Maximum operating pressure 350 bar

- Maximum flow 58 l/min

Download PDF

Proportional directional valves, pilot operated

4WRZ

- Size 10, 16, 25, 32, 52

- Component series 7X

- Maximum operating pressure 350 bar

- Maximum flow 2800 l/min

Download PDF

4WRZE

- Size 10, 16, 25, 32, 52

- Component series 7X

- Maximum operating pressure 350 bar

- Maximum flow 2800 l/min

Download PDF

4WRZ ...XE

- Size 10, 16, 25, 32

- Component series 7X

- Maximum operating pressure 350 bar

- Maximum flow 1600 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 2G

- Type of protection of the valve solenoids: Ex eb mb IIC T4 Gb according to EN 60079-7 / EN 60079-18

Download PDF

4WRH

- Size 10, 16, 25, 32, 52

- Component series 7X

- Maximum operating pressure 350 bar

- Maximum flow 2800 l/min

Download PDF

5WRZ

- Size 52

- Component series 7X

- Maximum operating pressure 350 bar

- Maximum flow 2800 l/min

Download PDF

5WRZE

- Size 52

- Component series 7X

- Maximum operating pressure 350 bar

- Maximum flow 2800 l/min

Download PDF

5WRH

- Size 52

- Component series 7X

- Maximum operating pressure 350 bar

- Maximum flow 2800 l/min

Download PDF

4WRHM

- Size 10, 16, 25

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 870 l/min

Download PDF

4WRZM

- Size 10, 16, 25

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 870 l/min

Download PDF

4WRZEM

- Size 10, 16, 25

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 870 l/min

Download PDF

4WRKE

- Size 10, 16, 25, 27, 32, 35

- Component series 3X

- Maximum operating pressure 350 bar

- Maximum flow 3000 l/min

Download PDF

Proportional pressure reducing valves

Proportional pressure reducing valves, direct operated

3DREP(E) 6

- Size 6

- Component series 2X

- Max. operating pressure 100 bar

- Flow, max. 15 l/min

Download PDF

3DREP…XE

- Size 6

- Component series 2X

- Max. operating pressure 100 bar

- Flow, max. 15 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 2G

- Type of protection of the valve: Ex eb mb IIC T4 Gb according to EN 60079-7 / EN 60079-16

Download PDF

Proportional pressure reducing valves, pilot operated

DRE 6, DREE 6

- Size 6

- Component series 1X

- Max. operating pressure 315 bar

- Flow, max. 30 l/min

Download PDF

ZDRE 6, ZDREE 6

- Size 6

- Component series 1X

- Max. operating pressure 315 bar

- Flow, max. 30 l/min

Download PDF

ZDRE 10, ZDREE 10

- Size 10

- Component series 2X

- Max. operating pressure 315 bar

- Flow, max. 80 l/min

Download PDF

DRE(M) 10, DRE(M) 20

- Size 10, 25

- Component series 6X

- Max. operating pressure 315 bar

- Flow, max. 300 l/min

Download PDF

DRE(M)E 10, DRE(M)E 20

- Size 10, 25

- Component series 6X

- Max. operating pressure 315 bar

- Flow, max. 300 l/min

Download PDF

DRE(M) 30

- Size 32

- Component series 6X

- Max. operating pressure 315 bar

- Flow, max. 300 l/min

Download PDF

DRE(M)E 30

- Size 32

- Component series 6X

- Max. operating pressure 315 bar

- Flow, max. 300 l/min

Download PDF

3DRE(M)

- Size 10, 16

- Component series 7X

- Max. operating pressure 350 bar

- Flow, max. 300 l/min

Download PDF

3DRE(M)E

- Size 10, 16

- Component series 7X

- Max. operating pressure 350 bar

- Flow, max. 300 l/min

Download PDF

DREBE10Z

- Size 10

- Component series 1X

- Max. operating pressure 315 bar

- Flow, max. 120 l/min

Download PDF

DRG

- Size 10, 25, 30

- Component series 1X

- Max. operating pressure 315 bar

- Flow, max. 300 l/min

Download PDF

DRG_G

- Size 8, 10, 16, 20, 25, 32

- Component series 1X

- Max. operating pressure 315 bar

- Flow, max. 300 l/min

Download PDF

Proportional pressure control valves

From multiple direct to pilot-operated proportional pressure control valves, this range delivers a wide range of hydraulic flow capacity for any relieve circuit. Proportional pressure control valves have proven their reliability time and time again in literally millions of operational hours.

Proportional pressure relief valves

Proportional pressure relief valves, direct operated

DBETA

- Size 6

- Component series 6X

- Maximum operating pressure 500 bar

- Maximum flow 5 l/min

Download PDF

DBETBX

- Size 6

- Component series 1X

- Maximum operating pressure 315 bar

- Nominal flow 1 l/min

Download PDF

DBETBEX

- Size 6

- Component series 1X

- Maximum operating pressure 315 bar

- Nominal flow 1 l/min

Download PDF

DBET

- Size 6

- Component series 6X

- Maximum operating pressure 420 bar

- Maximum flow 2 l/min

Download PDF

DBETE

- Size 6

- Component series 6X

- Maximum operating pressure 420 bar

- Maximum flow 2 l/min

Download PDF

DBET...XE

- Size 6

- Component series 6X

- Maximum operating pressure 420 bar

- Nominal flow 2 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 2G; II 2D

- Type of protection of the valve solenoids:

• gas: eb (EN 60079-7), mb (EN 60079-18)

• dust: tb (EN 60079-31)

Download PDF

DBGT

- Size 6

- Component series 2X

- Maximum operating pressure 700 bar

- Maximum flow 12 l/min

Download PDF

KBPS.8A

- Size 8

- Component series A

- Maximum operating pressure 420 bar

- Maximum flow 2 l/min

Download PDF

KBPS.8B

- Size 8

- Component series A

- Maximum operating pressure 420 bar

- Maximum flow 2 l/min

Download PDF

Proportional pressure relief valves, pilot operated

DBEBE10Z

- Size 10

- Component series 1X

- Max. operating pressure 315 bar

- Flow, max. 120 l/min

Download PDF

(Z)DBE 6, (Z)DBEE 6

- Size 6

- Component series 2X

- Max. operating pressure 350 bar

- Flow, max. 30 l/min

Download PDF

High-response directional valves

High-response valves are compact and robust. They boast high dynamics and closed-loop accuracy in position, velocity, pressure and force control applications. Find the high-response valve you need to control the start, stop and direction of circuit fluid flow.

High-response directional valves, direct operated

4WRPE

- Size 10

- Component series 3X

- Maximum operating pressure 350 bar

- Nominal flow 50 … 80 l/min

Download PDF

4WRPH 6

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 40 l/min

- Nominal flow 2 … 40 l/min

Download PDF

4WRPH 10

- Size 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 100 l/min

- Nominal flow 50 … 100 l/min

Download PDF

4WRPH..2X..-750

- Size 6, 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 100 l/min

- Nominal flow 12 … 100 l/min

Download PDF

4WRPEH 6 -2X

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Nominal flow 2 … 40 l/min

Download PDF

4WRPEH 6 -3X

- Size 6

- Component series 3X

- Maximum operating pressure 350 bar

- Nominal flow 4 … 40 l/min

- Digital interface IO-Link for I4.0

Download PDF

4WRPEH 10

- Size 10

- Component series 2X

- Maximum operating pressure 315 bar

- Nominal flow 50 … 100 l/min

Download PDF

4WRPDH

- Size 6, 10

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 100 l/min

Download PDF

4WRPNH../24C/P

- Size 6, 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 100 l/min

Download PDF

4WRPNH../24F..

- Size 6, 10

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 100 l/min

Download PDF

4WRSE

- Size 6, 10

- Component series 3X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Nominal flow 4 … 75 l/min

Download PDF

High-response directional valves, pilot operated

4WRLD -4X

- Size 10 … 35

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 4700 l/min

- Nominal flow 60 … 1500 l/min

Download PDF

4WRLE

- Size 10 … 35

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 4700 l/min

- Nominal flow 60 … 1500 l/min

Download PDF

4WRVE

- Size 10 … 27

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 1000 l/min

- Nominal flow 40 … 430 l/min

Download PDF

4WRGE

- Size 10 … 25

- Component series 1X

- Maximum operating pressure 350 bar

- Maximum flow 870 l/min

- Nominal flow 50 … 350 l/min

Download PDF

4WRTE

- Size 10 … 35

- Component series 4X

- Maximum operating pressure 350 bar

- Maximum flow 3000 l/min

- Nominal flow 25 … 1000 l/min

Download PDF

4WRDE -5X

- Size 10 … 35

- Component series 5X

- Maximum operating pressure 350 bar

- Maximum flow 3000 l/min

- Nominal flow 25 … 1000 l/min

Download PDF

4WRDE -6X

- Size 10 … 27

- Component series 6X

- Maximum operating pressure 350 bar

- Maximum flow 1000 l/min

- Nominal flow 25 … 500 l/min

Download PDF

Proportional flow control valves

Optimize machines and assembly line performance with Bosch Rexroth’s proportional flow control valves, and keep the flow constant when the load forces change.

Proportional flow control valves

2FRE

- Size 10, 16

- Component series 4X

- Max. operating pressure 315 bar

- Flow, max. 160 l/min

Download PDF

Directional servo-valves

Directional servo-valves are hydraulically pilot operated 2-stage or 3-stage directional valves. Because of their high dynamics they are used predominantly for the closed-loop controls of position, force or pressure, and velocity. Bosch Rexroth hydraulic servo-valves lead in controlling pressure, flow or position.

4WS.2E...

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 48 l/min

Download PDF

4WS2EM 6…XN

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 48 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Types of protection:

– Ex nA II T5X according to EN 60079-0 / EN 60079-15

– Ex tD A22 IP 65 TX according to EN 61241-0 / EN 61241-1

Download PDF

4WS2EM 6…XN-100

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 48 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Types of protection:

– Ex nA II T5X according to EN 60079-0 / EN 60079-15

– Ex tD A22 IP 65 TX according to EN 61241-0 / EN 61241-1

Download PDF

4WS2EM 6…XN-102

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 48 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Types of protection:

– Ex nA II T5X according to EN 60079-0 / EN 60079-15

– Ex tD A22 IP 65 TX according to EN 61241-0 / EN 61241-1

Download PDF

4WS2EM 6…XL

- Size 6

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 48 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G

- Type of protection: Ex ic IIC T4 Gc according to EN 60079-0 / EN 60079-11

Download PDF

4WS.2E...

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

Download PDF

4WS2EM 10…XD

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 2G

- Types of protection of the valve: Ex db IIC T4 Gb according to EN 60079-0 / EN 60079-1 and IEC 60079-0 / IEC 60079-1

Download PDF

4WS2EM 10…XD...-100

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 2G

- Types of protection of the valve: Ex db IIB T4 Gb acc. to EN 60079-0 / EN 60079-1 and IEC 60079-0 / IEC 60079-1

Download PDF

4WS2EM 10…XH

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 1G

- Type of protection: Ex ia IIC T4 Ga according to EN 60079-0 / EN 60079-11

Download PDF

4WS2EM 10…XH...-102

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 1G

- Type of protection: Ex ia IIC T4 Ga according to EN 60079-0 / EN 60079-11

Download PDF

4WS2EM 10…XH...-104

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 1G

- Type of protection: Ex ia IIC T4 Ga according to EN 60079-0 / EN 60079-11

Download PDF

4WS2EM 10…XN

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Types of protection:

– Ex nA II T5X according to EN 60079-0 / EN 60079-15

– Ex tD A22 IP 65 TX according to EN 61241-0 / EN 61241-1

Download PDF

4WS2EM 10…XN...-100

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Types of protection:

– Ex nA II T5X according to EN 60079-0 / EN 60079-15

– Ex tD A22 IP 65 TX according to EN 61241-0 / EN 61241-1

Download PDF

4WS2EM 10…XN...-102

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Types of protection:

– Ex nA II T5X according to EN 60079-0 / EN 60079-15

– Ex tD A22 IP 65 TX according to EN 61241-0 / EN 61241-1

Download PDF

4WS2EM 10…XN...-114

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G; II 3D

- Types of protection:

– Ex nA II T5X according to EN 60079-0 / EN 60079-15

– Ex tD A22 IP 65 TX according to EN 61241-0 / EN 61241-1

Download PDF

4WS2EM 10…XL

- Size 10

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 180 l/min

- Area of application in accordance with the Explosion Protection Directive 2014/34/EU: II 3G

- Type of protection: Ex ic IIC T4 Gc according to EN 60079-0 / EN 60079-11

Download PDF

4WS(E)2E. 16

- Size 16

- Component series 2X

- Maximum operating pressure 315 bar

- Maximum flow 320 l/min

Download PDF

4WSE3E 16

- Size 16

- Component series 2X

- Maximum operating pressure 350 bar

- Maximum flow 570 l/min

Download PDF

4WSE3E 25

- Size 25

- Component series 3X

- Maximum operating pressure 350 bar

- Maximum flow 1020 l/min

Download PDF

4WSE3E 32

- Size 32

- Component series 5X

- Maximum operating pressure 315 bar

- Maximum flow 1800 l/min

Download PDF

Cartridge valves

Proportional directional valves

2WFC; 2WFCE

- Size 16, 25, 32, 40, 50

- Component series 1X

- Maximum operating pressure 420 bar

- Maximum flow 1500 l/min